Invariably the used of a forced air cooling device is not only concerned with adequate cooling of his equipment but also with the amount of power required to accomplish this cooling. The factors influencing the operating efficiency of an air moving device are:

- Flow and pressure range

- The operating speed range

- The motor which powers the air mover

- Any electrical or electronic device used to modify the electrical supply into the motor

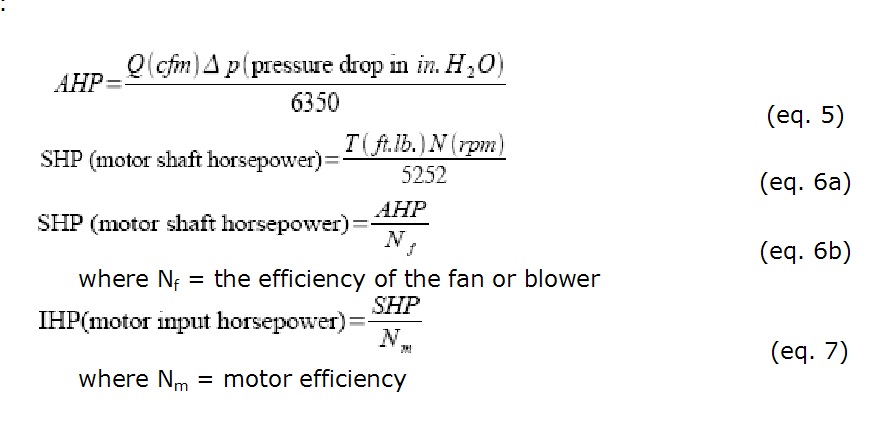

These variables are related to efficiency at specific operating points as shown in the following formula:

Overall efficiency of the cooling device, adding N or the efficiency of any electrical/electronic supply modifying componentry, is then:

For best efficiency, as well as minimum noise, an air mover should generally be operated at 50% or more of its peak efficiency. The best efficiency point, BEP, is usually in the middle 2/3 of the flow rate range.